In today’s fast-paced manufacturing world, turning a digital design into a finished part quickly and reliably is a huge competitive edge. At NE Solution, our streamlined workflow takes your ideas from CAD files to finished products, combining engineering know-how, secure online tools, and rapid delivery—so you can move from concept to reality with confidence.

Whether you’re an engineer refining a prototype, a business owner needing a custom part, or a manufacturer looking to scale, our end-to-end process ensures expert support, confidentiality, and quality at every step.

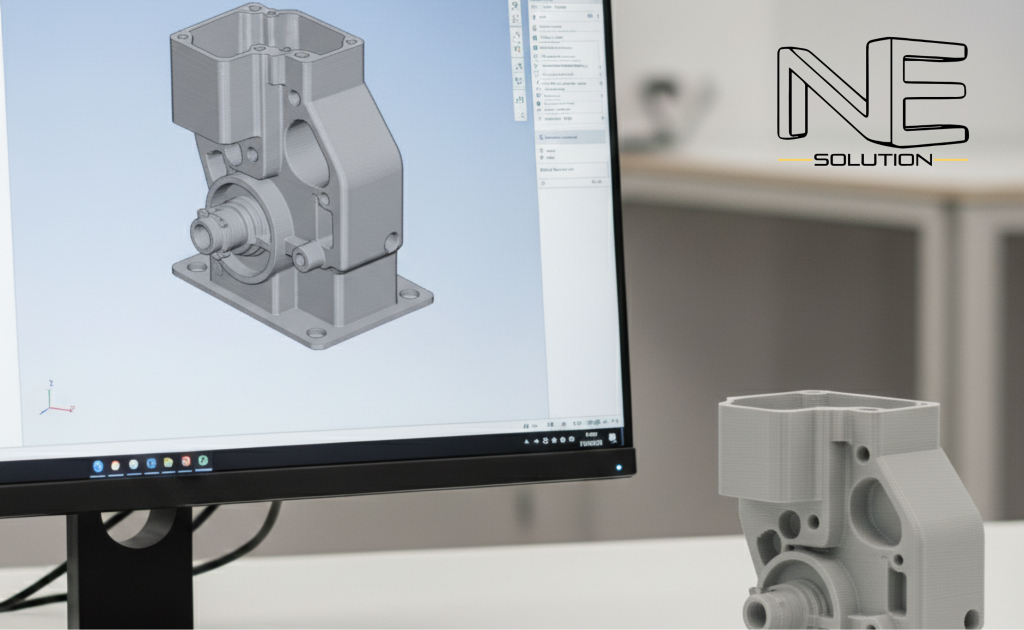

1. Engineering Design & CAD Modelling

Every successful 3D printing project starts with a solid digital foundation. At NE Solution, we provide comprehensive engineering design and modelling services using Autodesk Inventor and other industry-standard tools. We create 2D and 3D CAD drawings, assembly diagrams, schematics, and DXFs for laser cutting.

We know that even small errors in design files—like open surfaces or faulty geometry—can cause major issues down the line. That’s why we review every file for printability, provide feedback or fixes as needed, and work with you to ensure your design is ready for manufacturing. Our expertise means fewer surprises, faster turnaround, and a better finished product.

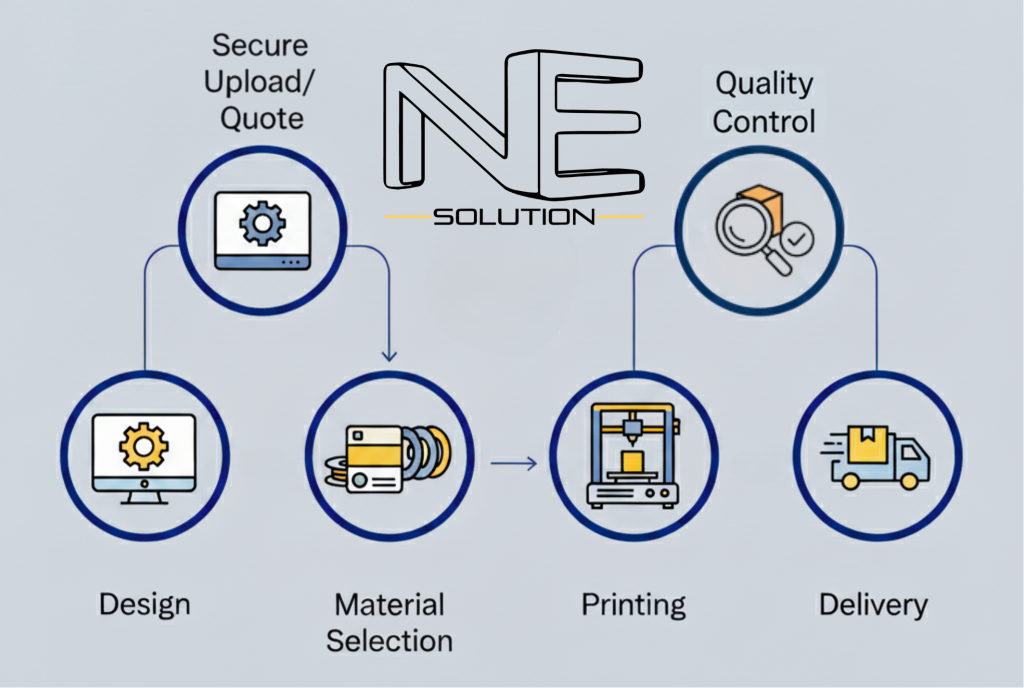

2. Secure File Upload & Instant Quote

Once your design is ready, uploading it for production is simple and secure. Our online instant quote tool lets you submit your CAD files confidentially, select your desired materials and technologies, and get a fast, transparent estimate—no back-and-forth emails required.

We’re committed to protecting your intellectual property. All uploads are handled with strict confidentiality, so you can trust your designs are safe.

3. Material & Technology Selection

With your files uploaded, it’s time to choose the right material and 3D printing technology for your project. We offer a broad range of materials—including Nylon, PLA, ABS, PETG, and stainless steel—to suit everything from functional prototypes to production parts.

Not sure which process fits best? We’ll help you compare FDM, SLS, SLA, and SLM technologies, weighing up factors like strength, finish, size, and cost. Our goal is to match your requirements to the ideal combination for performance and value.

4. Rapid Prototyping & Production

Whether you need a single prototype, a small batch, or a full production run, NE Solution can deliver. Our in-house capabilities are backed up by trusted local and international manufacturing partners, letting us handle jobs of any size and complexity.

We pride ourselves on flexibility—supporting everything from one-off engineering prototypes to large-scale runs for major clients. With efficient project management and streamlined supply chain services, we keep your project on track and on time.

5. Quality Control & Post-Processing

Quality is non-negotiable. Every part we produce goes through a rigorous inspection checklist before delivery. We also offer post-processing services like finishing, painting, and assembly, either in-house or through specialist partners, to ensure your parts aren’t just functional—they look the part, too.

Our engineering oversight and attention to detail mean you get reliable results, every time.

6. Delivery & Ongoing Support

Once your parts pass inspection, we move fast to get them to you—whether you’re in Sydney or further afield. Our streamlined logistics and local production mean rapid turnaround, and we’re always available for support or troubleshooting after delivery.

At NE Solution, you’re not just getting a print—you’re getting a partner invested in your success.

Conclusion

From the first CAD sketch to the finished product, NE Solution delivers a seamless, engineering-driven 3D printing experience. With expert guidance, secure online tools, flexible production, and a commitment to quality, we help you bring your ideas to life—fast.

Ready to see your next project go from CAD to reality? Get an instant quote today.

0/5

(0 Reviews)