In heavy industries like mining, when a critical component like a large-scale gear fails, the cost of operational downtime is enormous. We were tasked with a high-stakes project: a client had several large, damaged industrial gears—and no original CAD files or drawings to re-manufacture them.

The Challenge

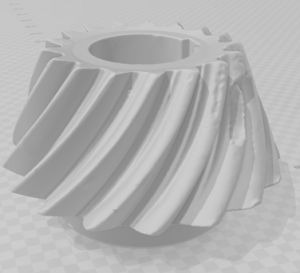

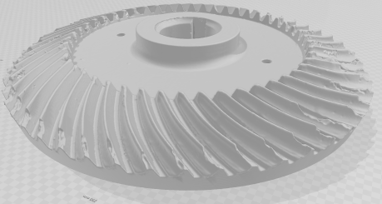

A client in a heavy industry, likely a mining operation, was faced with critical machinery failure due to damaged spiral bevel gears. These were large, complex, and high-value components. The original manufacturer’s (OEM) lead times for replacements were measured in months, not weeks, which meant an unacceptable loss of production.

The client needed to get these parts re-manufactured locally and quickly, but they had no digital models or technical drawings to work from.

The Solution

The client shipped the heavy, damaged components to our facility. Our solution was to create a precise digital blueprint of the parts using high-precision 3D scanning.

-

High-Precision 3D Scanning: Using our advanced scanning equipment, we meticulously captured the complex geometry of both the spiral bevel ring gear and the pinion gear.

-

Data Processing: Even with surface damage and wear, our scanners and software can capture the core geometry. We processed this raw scan data into clean, accurate, and watertight 3D models.

-

Digital Delivery: We provided the client with the final high-resolution 3D models (scanned copies) along with detailed dimensional reports extracted from the data.

The Outcome

Instead of waiting months for an OEM replacement, the client was provided with the critical 3D scan files and dimensions within days.

This digital data empowered them to immediately engage their preferred machine shop for reverse engineering and local re-manufacturing. By creating a ‘digital twin’ of their critical parts, the client is no longer reliant on long-lead-time suppliers and has a permanent digital record for any future manufacturing needs, significantly reducing the impact of future downtime.

Critical Part Failure? No Drawings?

Don’t let a broken component stop your entire operation. Our industrial 3D scanning services provide the fast, accurate data you need for reverse engineering and re-manufacturing. Contact us to digitise your critical components and get back online faster.

Enquire About 3D Scanning