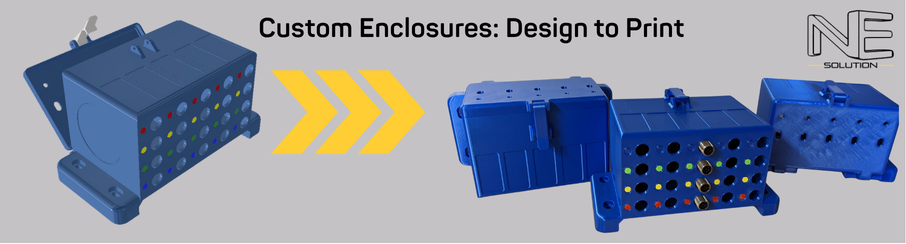

Finding an off-the-shelf electrical enclosure that precisely fits your components, port layouts, and mounting requirements is nearly impossible. A client came to us with this exact problem: they needed a completely custom 3D printed enclosures designed box for their electronics. This project showcases our full end-to-end design and manufacturing service.

The Challenge

The client required an enclosure for a new electronic product. This box needed a highly specific layout for connectors, ports, and internal mounting points. No standard-molded box on the market would work. Furthermore, they needed a production run of these enclosures, but not enough to justify the massive tooling costs and long lead times of traditional injection molding.

The Solution

Our team managed the entire process from a simple idea to a finished batch of products.

Consultation & Design: We started with a detailed consultation to understand the client’s exact requirements—dimensions, port layout, material properties, and mounting strategy.

3D Modeling & Prototyping: Our engineers designed a complete 3D model of the enclosure from scratch. We submitted this digital model to the client for review and approval, allowing them to visualize the product and request changes before anything was made.

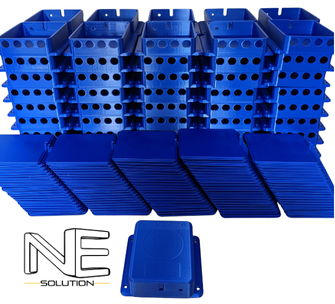

Low-Volume Manufacturing: Once the design was approved, we moved straight to production. Using our in-house 3D printing capabilities, we manufactured a full batch of the enclosures and their matching lids. This “digital manufacturing” approach means zero tooling costs and incredible speed.

This image shows the completed production run of a smaller iteration, demonstrating our ability to handle low-volume manufacturing, not just one-off prototypes.

The Outcome

The client received a batch of perfectly fitting, durable, and professional-grade enclosures, ready for their final product assembly. They were able to move from concept to a manufactured part in a fraction of the time and at a fraction of the cost of traditional molding.

This project highlights our ability to be a true partner, bridging the gap between an idea, a prototype, and scalable low-volume production.

Need a Custom Enclosure for Your Product?

Stop trying to make an off-the-shelf box fit. We can design, prototype, and manufacture a custom enclosure that is built specifically for your needs.

Start Your Custom Design