Remember when 3D printing felt like science fiction? A cool gadget churning out plastic models and maybe a replacement knob for the dishwasher? Fun, perhaps, but maybe not truly industrial. Well, think again. That perception is rapidly becoming a relic. Right now, in 2025, Additive Manufacturing (AM), the industrial sibling of 3D printing, is undergoing a seismic shift – moving decisively out of the R&D labs and onto the humming factory floor.

The era where AM was primarily the go-to tool for rapid prototyping, for churning out quick visual models or fit-test parts, is evolving. We’re witnessing its powerful transformation into a full-scale production powerhouse. The focus has pivoted sharply from simply visualising a product to manufacturing the final, functional, mission-critical end-use parts themselves.

Imagine jet engine components with internal cooling channels so complex they’re impossible to cast or machine. Picture patient-specific surgical implants, perfectly matched to an individual’s anatomy for better outcomes. Visualise lightweight, high-strength parts for next-generation electric vehicles or critical components for defence systems produced on demand. This isn’t future-gazing; it’s happening now.

What’s driving this industrial revolution, layer by layer? It’s a convergence of breakthroughs. AM excels at creating incredibly complex geometries that traditional methods struggle with. It unlocks unprecedented customisation, vital in fields like healthcare. Crucially, advancements in speed, reliability, and materials science mean AM can now produce parts with the strength, durability, and precision required for the most demanding applications.

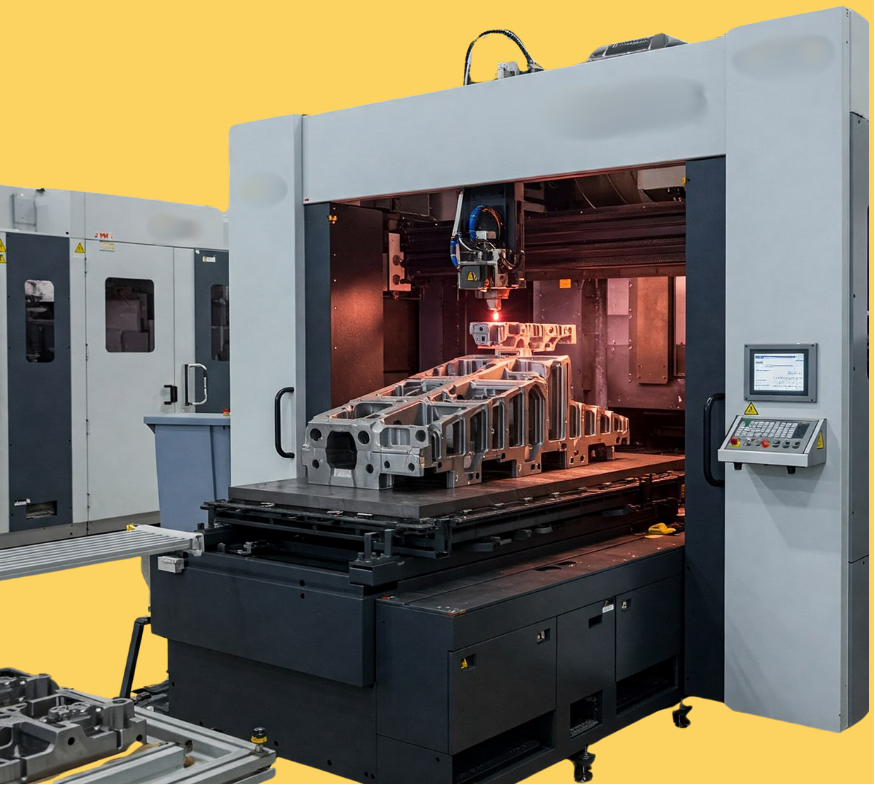

This isn’t your hobbyist’s desktop printer scaled up slightly. Industrialisation means scaling production. Think entire fleets of sophisticated printers working in synchronised harmony, monitored by intelligent software. Picture large-format systems capable of printing components measured in metres, not millimetres. Envision advanced multi-laser machines fusing metal or polymer powders at speeds that dramatically shorten production times. Often, accessing this level of industrial technology is done through a specialized 3d printing service, making these advanced capabilities available without massive capital investment.

The impact is reverberating through high-stakes industries:

- Aerospace & Defense: Building lighter, stronger components means more fuel-efficient aircraft and spacecraft. On-demand printing capabilities can revolutionise maintenance and supply chains for military hardware.

- Automotive: Rapidly producing custom jigs, fixtures, and tooling slashes development times. Manufacturing complex, performance-enhancing parts helps drive innovation in vehicle design.

- Healthcare: Creating bespoke implants and surgical guides tailored to individual patients is transforming treatments and improving quality of life.

Harnessing this industrial shift is becoming increasingly accessible. Companies across Australia, from innovative startups to established manufacturers and beyond, are leveraging these advanced capabilities. Service providers like NE Solution offer a comprehensive 3d printing service, bridging the gap with expertise and access to industrial-grade machines for businesses looking to produce high-quality end-use parts, prototypes, or tooling. Curious about how AM could benefit your specific project? You can even explore the possibilities and get an initial idea of costs instantly using tools like their online quote platform.

This isn’t just about adding a new tool to the manufacturing toolbox; it’s about fundamentally changing how things are made. It signals a move towards more agile, responsive, and potentially localised manufacturing. It allows engineers to design for optimal function, freed from many traditional manufacturing constraints.

So, the next time you hear about 3D printing, look beyond the initial ‘wow’ factor of a plastic model appearing from nowhere. See the reality: robust machines building critical parts for planes, cars, and even human bodies, often facilitated by expert providers. Additive Manufacturing has stepped up. It’s no longer just dreaming up the future; it’s busy building it, right now, on the factory floor.