The Australian manufacturing landscape is dynamic and demanding. Fabricators, machinists, tooling shops, and assembly operations across the country face constant pressure to innovate, increase efficiency, reduce costs, and shorten lead times to remain competitive globally and domestically. In this high-stakes environment, adopting advanced technologies isn’t just an option; it’s essential for survival and growth. Additive Manufacturing (AM), more commonly known as 3D printing, has emerged from a niche prototyping technology into a powerful mainstream manufacturing tool, offering tangible solutions to many of these challenges, particularly in the critical areas of design verification and custom tooling production.

For many Australian manufacturers, the traditional path from design to finished part involves significant time, cost, and risk. Errors caught late in the process, complex tooling requirements, and the inflexibility of conventional methods can lead to budget overruns and project delays. 3D printing offers a fundamentally different approach, enabling rapid iteration, unprecedented design freedom, and significant cost savings. This article explores how leveraging 3D printing, particularly through expert service providers like NE Solution, can revolutionise design validation before expensive machining begins and transform the way custom tools, jigs, and fixtures are created on the factory floor.

1. Overcoming Design Hurdles: Fast, Tangible Verification Before Machining

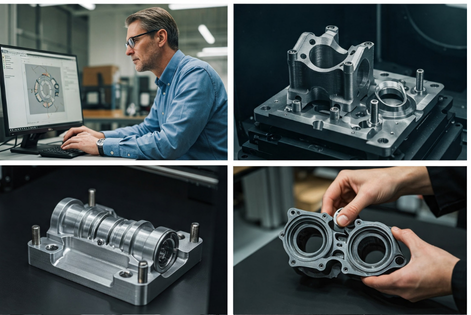

One of the most significant risks in manufacturing is discovering a design flaw after committing to expensive tooling or complex machining operations. A slight miscalculation in clearance, an unforeseen assembly issue, or poor ergonomics can lead to costly rework, wasted materials, and significant delays. This is where 3D printing shines as a premier tool for rapid prototyping and design verification.

- Speed: Instead of waiting weeks for a machined prototype or relying solely on CAD simulations, 3D printing can turn a digital design file into a physical, tangible object often within hours or days. This dramatic acceleration allows engineers and designers to get real-world feedback almost immediately.

- Cost-Effectiveness: Traditional prototypes often require dedicated setups or even preliminary tooling, making iterations expensive. 3D printing eliminates these tooling costs for the prototyping phase. Prototypes can be printed for the cost of materials and machine time, making it economically viable to test multiple design variations concurrently or sequentially.

- Tangible Testing: A physical prototype allows for true form, fit, and function testing. Machinists can check clearances against mating parts, assembly teams can evaluate handling and access, and ergonomic factors can be assessed in a way impossible with purely digital models. Holding a part, testing its fit, and simulating its use provides invaluable insights early in the development cycle.

- Early Error Detection & Faster Iteration: By identifying flaws early through physical prototypes, costly mistakes downstream are avoided. Design modifications can be made quickly in CAD, and a revised prototype printed rapidly, creating a fast, efficient feedback loop that refines the design far quicker than traditional methods allow. This iterative process, facilitated by 3D printing, significantly reduces the risk associated with launching a new product or component.

- Material Versatility: Depending on the verification needed, prototypes can be printed in various materials – from basic, low-cost plastics for form and fit checks to engineering-grade polymers that mimic the mechanical properties of the final product for functional testing.

For Australian fabricators and machinists, this means greater confidence before committing valuable machine time and resources. It fosters better communication between design and production teams, ensuring the final part is not only functional but also manufacturable efficiently.

2. Smarter Tooling: Custom Jigs, Fixtures, and Aids On-Demand

Beyond prototyping, 3D printing is profoundly impacting the creation of tooling – the essential jigs, fixtures, gauges, and other devices that guide, hold, and check parts during manufacturing and assembly processes. Traditionally, these tools are CNC machined from metal or durable plastic, a process that is often:

- Slow: Lead times for machined tooling can stretch to weeks or even months, especially if outsourced.

- Expensive: The combination of design time, programming, machine setup, material costs, and skilled labour makes traditional tooling a significant investment, particularly for custom or low-volume requirements.

- Inflexible: Once a tool is machined, modifications are difficult and costly. Designs often involve compromises due to the limitations of subtractive manufacturing.

3D printing flips this paradigm on its head, offering a compelling alternative for creating a wide range of manufacturing aids:

- Dramatic Cost and Time Savings: Studies and real-world applications consistently show that 3D printing jigs and fixtures can reduce costs by up to 98% and lead times by up to 89% compared to conventional methods. Imagine designing a custom fixture in the morning and having it ready for use on the assembly line the next day, for a fraction of the cost of a machined equivalent.

- Unmatched Design Freedom: Additive manufacturing builds parts layer by layer, enabling the creation of highly complex, organic shapes, internal channels, and lightweight structures that are difficult or impossible to machine. This allows for tools that are perfectly contoured to the workpiece, more ergonomic for operators (lighter weight reduces fatigue), and optimised for specific tasks.

- Material Choice: Modern 3D printing offers a wide array of durable materials suitable for demanding factory environments, including tough polymers, high-temperature resistant resins, flexible materials, and even composites reinforced with carbon fibre or kevlar for added strength and stiffness. The right material can be selected for the specific application, whether it’s a simple alignment jig or a robust workholding fixture.

- On-Demand Production & Reduced Inventory: Instead of maintaining large inventories of physical tools, designs can be stored digitally and printed only when needed. A broken fixture can be reprinted overnight, minimising downtime. This agility is invaluable in fast-paced production environments or for high-mix, low-volume manufacturing common in Australia.

- Common Applications: Examples include custom soft jaws for vices, drill guides, welding fixtures, go/no-go gauges for quality control, assembly aids, protective covers, templates, and end-of-arm tooling (EOAT) for robotic automation – often lighter and more customised than traditional metal EOAT.

For Australian tooling shops, machine shops, and assembly operations, integrating 3D printed tooling means increased agility, faster response to production changes, improved workflow efficiency, and significant operational cost reductions.

3. The Additive Advantage for Australian Manufacturers

The benefits of 3D printing for design verification and tooling directly address key priorities for the Australian manufacturing sector. By reducing upfront costs and development time, AM lowers the barrier to innovation, allowing businesses to bring better products to market faster. The ability to create complex geometries opens doors to novel designs and solutions previously unachievable.

Furthermore, as the push for onshoring and strengthening local supply chains continues, 3D printing offers a powerful capability for localised, on-demand manufacturing. It reduces reliance on overseas suppliers for prototypes and tooling, increasing resilience and responsiveness. Recognised by the government as a critical technology, AM aligns perfectly with national priorities in advanced manufacturing. It is particularly well-suited to the bespoke, high-value, and customised manufacturing niches where Australian industry often excels.

4. Partnering for Success: Leveraging 3D Printing Services

While the benefits are clear, adopting AM technology in-house can involve investment in hardware, materials, and expertise. Recent market trends show growth in AM services, highlighting that many businesses prefer to leverage external expertise. Partnering with a dedicated 3D printing service provider like NE Solution offers Australian manufacturers immediate access to these transformative capabilities without the significant upfront capital expenditure.

NE Solution provides expertise across various 3D printing technologies (e.g., FDM, SLA, SLS) and a wide range of materials. We work collaboratively with clients – from fabricators and machinists to design engineers – to understand their specific needs for design verification or custom tooling. We help select the optimal process and material to achieve the desired outcome, whether it’s a quick visual prototype, a functional test part, or a durable, factory-ready fixture. By outsourcing your 3D printing needs to us, you gain flexibility, speed, and cost-efficiency, allowing you to focus on your core manufacturing competencies.

Conclusion: Embrace the Future of Manufacturing

Additive Manufacturing is no longer a futuristic concept; it’s a practical, accessible technology delivering real-world advantages today. For Australian manufacturers, 3D printing offers a powerful pathway to streamline design verification, slash tooling costs and lead times, and unlock new levels of innovation and efficiency. By reducing risk in the design phase and enabling the rapid creation of custom manufacturing aids, AM provides a significant competitive edge. Whether through in-house adoption or partnership with expert service providers, embracing 3D printing is key to thriving in the evolving manufacturing landscape.

Ready to reduce lead times, cut costs, and innovate faster? Explore how 3D printing can transform your manufacturing processes. Contact NE Solution today for a consultation and discover the possibilities of additive manufacturing for your Australian business. Visit N.E. Solution to learn more.