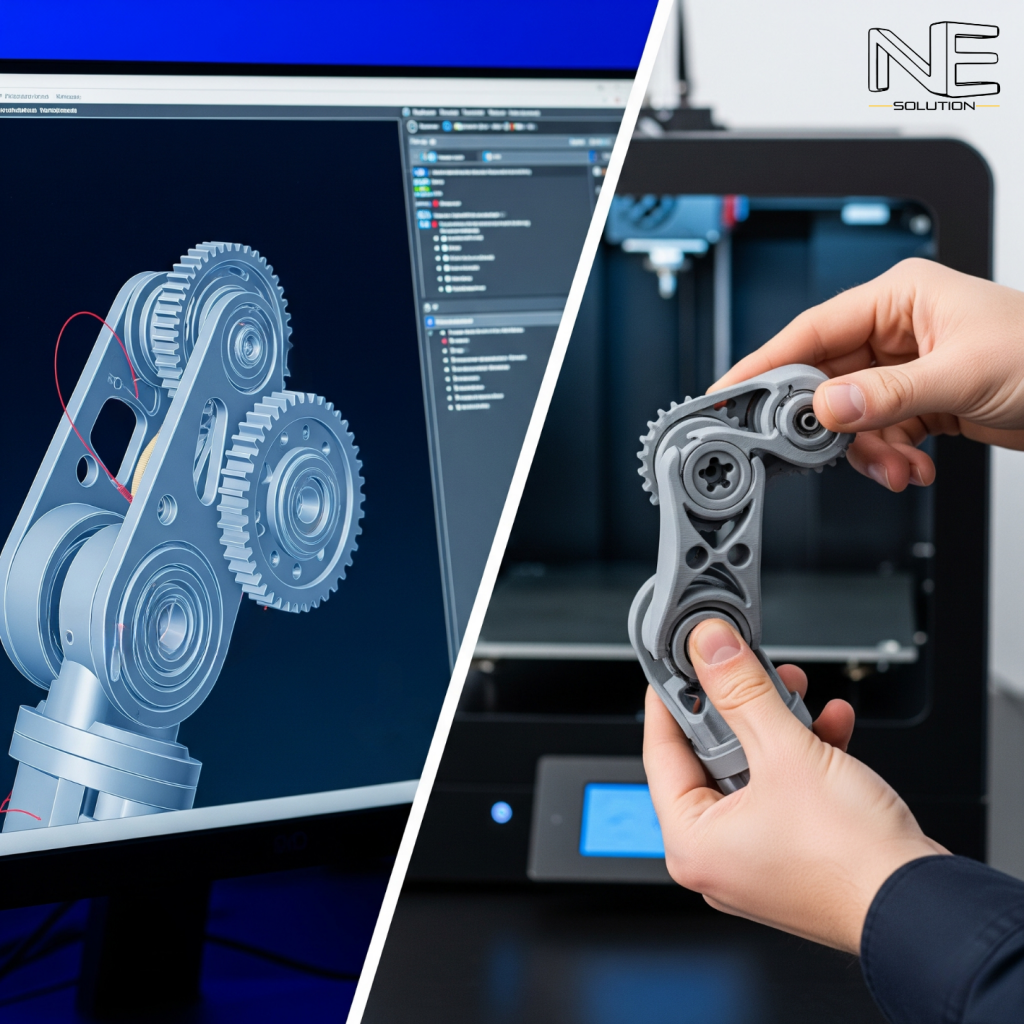

The robotics industry is advancing at an unprecedented pace, and a key technology underpinning this rapid development is 3D printing, also known as additive manufacturing. This isn’t just a futuristic concept; it’s a practical reality transforming how robots are designed, tested, and deployed. For innovators in Australia and globally, professional 3D printing services are crucial enablers, offering pathways to faster rapid prototyping and the creation of highly customised end-use parts. This article delves into the significant impact additive manufacturing has on robotics, exploring how leveraging expert 3D printing services, like those at nesolution.com.au, can propel your robotics projects from concept to reality with greater efficiency and innovation.

The Powerful Partnership: Robotics and Additive Manufacturing

Robotics inherently demands components that are often complex, highly specific, and lightweight. Traditional manufacturing techniques, while mature, can introduce bottlenecks in terms of cost, lead time, and design flexibility – particularly challenging given the iterative nature of robotics development and the frequent need for bespoke parts. 3D printing services offer a transformative alternative.

The advantages of using 3D printing services for robotics include:

- Complex Geometries Without Penalty: Robots frequently need intricate designs for optimal performance, such as internal cooling channels, lightweight yet strong lattice structures, or uniquely shaped grippers. 3D printing can produce these complex forms as a single piece, something often impossible or prohibitively expensive with traditional methods like CNC machining or injection moulding.

- Cost-Effective Customisation: Unlike mass production which thrives on uniformity, 3D printing excels in creating one-off or small batches of customised parts. In robotics, this translates to components perfectly tailored to specific tasks, environments, or even for creating custom robotics solutions.

- Optimised for Lightweighting: Reducing weight is critical in robotics for enhancing speed, manoeuvrability, and energy efficiency. Additive manufacturing allows for precise material placement and the use of advanced, lightweight materials, enabling the creation of strong parts with minimal mass.

- Part Consolidation: What might traditionally be an assembly of multiple components can often be redesigned and 3D printed as a single, integrated unit. This simplifies the bill of materials (BOM), reduces assembly time, and minimises potential points of failure.

These benefits clearly illustrate why 3D printing technology is such a powerful partner for the robotics industry.

Accelerating the Design Cycle: 3D Printing for Rapid Robotics Prototyping 🚀

The prototyping stage is fundamental to robotics, a phase of intense iteration to perfect form, fit, and function. Historically, this could be a slow and expensive process, with long waits for machined parts or costly tooling adjustments for minor design tweaks. 3D printing services have fundamentally changed this, enabling genuine rapid prototyping.

Key benefits for robotics prototyping include:

- Unmatched Speed and Iteration: The ability to go from a CAD design to a physical part in hours or a few days, rather than weeks, is the standout advantage. This allows engineers to quickly test designs, identify flaws, and iterate. Multiple versions of a component can be printed and evaluated almost simultaneously, significantly compressing the development timeline. For Australian businesses needing quick turnarounds, local 3D printing services like nesolution.com.au offer a distinct advantage.

- Significant Cost Reduction: The high setup costs associated with traditional prototyping (e.g., moulds, CNC programming for single parts) are eliminated with 3D printing. This makes producing numerous iterations economically feasible. Furthermore, as an additive process, material waste is drastically reduced.

- Effective Functional Testing: Leading 3D printing services offer a diverse portfolio of engineering-grade materials, including robust plastics like ABS, PETG, Nylon, and even advanced composites and metals. This means prototypes aren’t just for show; they can be functional “work-alike” components capable of withstanding rigorous real-world testing, allowing for early validation of mechanical properties.

- Greater Design Freedom: Freed from many of the constraints of traditional manufacturing, designers can explore more innovative and complex solutions without being overly hampered by manufacturability concerns at the prototyping stage.

For robotics companies, especially startups and R&D departments in Australia, the capacity to iterate designs quickly and affordably through 3D printing services is a critical enabler for innovation and market responsiveness.

From Prototypes to Production: 3D Printing End-Use Parts in Robotics

While its dominance in prototyping is clear, 3D printing is increasingly being utilised for the manufacture of end-use parts – functional components integrated directly into final robotic systems. This progression is fueled by advancements in 3D printing technologies, a wider range of high-performance materials, and a growing appreciation for the unique production benefits of additive manufacturing.

Applications and advantages of 3D printed end-use parts in robotics:

- Custom End-of-Arm Tooling (EOAT): This is a leading application. Robotic arms often need specialised grippers, fixtures, or sensor mounts precisely tailored to the objects they handle or the tasks they perform. 3D printing services facilitate the rapid design and production of highly customised, lightweight EOAT. This is a key area for custom robotics solutions in Australia.

- Bespoke Robotic Components: From structural elements like chassis and brackets to complex internal parts like gear housings or actuator mounts, 3D printing allows for the creation of components perfectly optimised for their specific function within a robot. This is invaluable for specialised robotics or robots operating in unique environments.

- On-Demand Spare Parts & Reduced Inventory: Robotic system downtime can be very costly. Traditional supply chains for spare parts, particularly for older or highly specialised robots, can mean long lead times. 3D printing services enable the production of spare parts on demand, directly from digital files, thus reducing the need for large physical inventories and minimising downtime.

- Lightweight and Strong Performance Parts: Materials such as carbon fibre-reinforced nylons, polycarbonates, and other engineering-grade polymers allow for the creation of end-use parts that are both exceptionally strong and significantly lighter than traditionally manufactured alternatives. This directly contributes to improved robot performance, higher payload capacities, and reduced energy consumption.

- Viable Small to Medium Volume Production: For robotics companies needing parts in low to medium volumes, 3D printing can be more economical than investing in expensive tooling for processes like injection moulding. It offers a flexible production method that can readily adapt to design modifications without incurring substantial re-tooling expenses.

The quality and reliability of components produced by industrial 3D printing services now meet the stringent requirements of many demanding robotics applications, making additive manufacturing a genuine option for series production.

Key Materials and Technologies Driving Robotic Advancement

The versatility of 3D printing in robotics is greatly amplified by the expanding selection of advanced materials and sophisticated printing technologies available through professional 3D printing services.

Common materials used in robotics 3D printing include:

- PLA (Polylactic Acid): Often used for initial, low-cost prototypes for form and fit checks.

- ABS (Acrylonitrile Butadiene Styrene): Offers good strength and impact resistance, suitable for functional prototypes and some end-use applications.

- PETG (Polyethylene Terephthalate Glycol): A good balance of strength, durability, and ease of printing; often used for mechanical parts.

- Nylon (Polyamide): Known for its excellent strength, toughness, and wear resistance, making it ideal for gears and robust functional parts.

- TPU (Thermoplastic Polyurethane) & Flexible Materials: Enable the creation of rubber-like parts such as compliant grippers, seals, or vibration dampeners.

- Carbon Fibre-Infused Composites (e.g., Nylon-CF): Provide significantly enhanced stiffness and strength-to-weight ratios, excellent for high-performance structural components.

- Polycarbonate (PC): High strength, impact resistance, and good temperature resistance.

- Metals (e.g., Aluminium, Stainless Steel, Titanium): Utilised for parts requiring maximum strength, rigidity, or specific metallic properties. Metal 3D printing services (using technologies like DMLS or SLM) are increasingly accessible for critical robotic components.

Key 3D printing technologies offered by leading 3D printing services for robotics:

- Fused Deposition Modeling (FDM) / Fused Filament Fabrication (FFF): The most widely used technology, ideal for prototypes and many functional parts using a broad range of thermoplastics and composites.

- Stereolithography (SLA): Cures liquid resin with UV light, producing parts with high detail and smooth surface finishes, excellent for intricate prototypes and some end-use applications.

- Selective Laser Sintering (SLS): Fuses powdered materials (typically nylon) with a laser, creating strong, durable parts without the need for support structures, ideal for complex geometries and functional components.

- Multi Jet Fusion (MJF): Similar to SLS but often faster, producing robust nylon parts suitable for both functional prototypes and end-use applications.

- Direct Metal Laser Sintering (DMLS) / Selective Laser Melting (SLM): Fuse metal powders layer by layer, enabling the creation of complex, high-strength metal parts for demanding robotic applications.

The Australian Advantage: Leveraging Local 3D Printing Services for Robotics

For robotics companies in Australia, partnering with local 3D printing services like nesolution.com.au offers distinct advantages. These include faster shipping, easier communication and collaboration, support for local industry, and a better understanding of the specific needs and standards within the Australian market. Access to local expertise in additive manufacturing can significantly streamline development and production, helping Australian innovators compete on a global scale. Whether it’s for rapid prototyping or producing critical end-use parts for custom robotics solutions, Australian 3D printing services are poised to support the burgeoning robotics sector.

The Future is Additive: Trends in Robotics and 3D Printing

The synergy between robotics and 3D printing is only set to grow stronger. We can anticipate:

- Advanced Materials Development: Even more specialised materials with enhanced properties (e.g., conductivity, biocompatibility, extreme temperature resistance) will become available.

- Increased Automation in AM: More automated 3D printing workflows will improve efficiency and reduce costs for series production.

- AI and Generative Design: Artificial intelligence will play a greater role in optimising designs for 3D printing, creating incredibly efficient and complex robotic components.

- Distributed Manufacturing: The ability to 3D print parts on-site or near the point of use will further shorten supply chains and enable more responsive manufacturing.

Conclusion: Partnering for Success in the Robotic Age

3D printing services have undeniably become a cornerstone of modern robotics development and manufacturing. From accelerating rapid prototyping cycles to enabling the production of complex, customised end-use parts, additive manufacturing offers unparalleled advantages in speed, cost-efficiency, and design freedom. For businesses in Australia looking to innovate in the field of robotics, embracing the capabilities of professional 3D printing services is key to developing next-generation solutions. Nesolution.com.au stands ready to assist with your 3D printing services needs, helping you to harness this transformative technology for your custom robotics projects.