Perth, WA – The recent recall of a2 Milk Company’s Light Milk 2L in Western Australia due to potential Listeria monocytogenes contamination served as a stark public reminder of an ever-present challenge within the global food supply chain: ensuring absolute food safety. While a2 Milk acted commendably and swiftly to mitigate risks by recalling the affected batch (Use By 06/06 #41, sold at major retailers Woolworths, Aldi, and Coles in WA), and collaborated with health authorities, such incidents inevitably send ripples of concern among consumers and highlight the immense responsibility shouldered by food producers. This event, though localized, underscores a universal truth: the pursuit of food safety is a continuous journey of vigilance, innovation, and adaptation.

In today’s technologically advanced world, the food and beverage industry is increasingly turning to groundbreaking solutions to bolster its defenses against contamination and spoilage. Among these, 3D printing services (also known as additive manufacturing services) are emerging not just as a novel technology but as a transformative force, offering multifaceted applications that can significantly enhance food safety from the farm to the fork, or in this case, from the processing plant to the consumer’s fridge. For businesses like nesolution.com.au, which specialize in providing cutting-edge 3d printing services, the potential to contribute to a safer food future is both exciting and profoundly important.

This article delves deep into how professional 3d printing services are poised to redefine food safety paradigms, making food production lines more resilient, packaging more intelligent, and detection methods more rapid and precise, ultimately helping to prevent the kind of recalls that disrupt businesses and erode consumer trust.

The Expanding Role of 3D Printing Services in Fortifying the Food Industry

The link between an industrial manufacturing process like 3D printing and the organic, perishable nature of food might not seem direct at first glance. However, the true value of 3d printing services in this context lies in their ability to create the tools, components, and systems that ensure food is processed, packaged, and monitored with unprecedented levels of precision and safety.

1. Revolutionizing Pathogen Detection: Rapid, On-Site, and Precise

One of the most groundbreaking applications of 3d printing services in the food safety arena is the development of sophisticated, low-cost, and rapid pathogen detection systems. Traditional methods for identifying contaminants like Listeria monocytogenes, Salmonella, or E. coli often involve lengthy laboratory analyses, causing delays that can be critical when dealing with perishable goods.

- Miniaturized Diagnostic Laboratories: 3D printing services excel at creating complex microfluidic chips – often called “lab-on-a-chip” devices. These miniature platforms can integrate multiple laboratory functions onto a single chip just a few centimeters in size. The intricate channels, mixers, and reaction chambers required for these devices are perfectly suited to the high-resolution capabilities of modern 3D printers, particularly techniques like stereolithography (SLA) or PolyJet.

- Enhanced Sensitivity and Specificity: Researchers are leveraging 3d printing services to embed biosensors directly into these microfluidic chips. These sensors can be functionalized with antibodies or aptamers (synthetic DNA/RNA strands) that specifically bind to target pathogens. This direct binding event can then be translated into a measurable signal (optical, electrical, or electrochemical), allowing for highly sensitive and specific detection. For instance, 3D printed devices are being developed to detect Listeria at levels far below infectious doses, providing an early warning system.

- Speed and On-Site Capability: The ability to perform tests on-site within a food processing facility, rather than sending samples to an off-site lab, is a game-changer. 3D printing services can facilitate the creation of portable, user-friendly detection kits. This means results can be obtained in minutes or hours, not days, allowing for immediate corrective actions, such as isolating a contaminated batch or halting a production line before widespread distribution occurs. This rapid response is crucial in preventing large-scale recalls.

- Cost-Effectiveness: By enabling the creation of disposable, single-use diagnostic chips, 3d printing services can significantly lower the cost per test compared to traditional methods that require expensive equipment and skilled personnel. This democratization of testing makes it feasible for even small to medium-sized enterprises (SMEs) in the food sector to implement robust pathogen monitoring programs.

- Customization for Specific Needs: Food producers often face unique challenges based on their products and processing environments. Professional 3d printing services allow for the custom design and fabrication of detection devices tailored to specific pathogens of concern or integration into particular points in the production line.

2. Hygienic Design of Food Processing Equipment: Engineering Contamination Out

The very design of food processing machinery can inadvertently create havens for microbial growth. Complex assemblies, sharp corners, dead zones in pipework, and rough surface finishes can harbor bacteria like Listeria, which is notoriously persistent in food processing environments. This is where the design freedom offered by 3d printing services becomes invaluable.

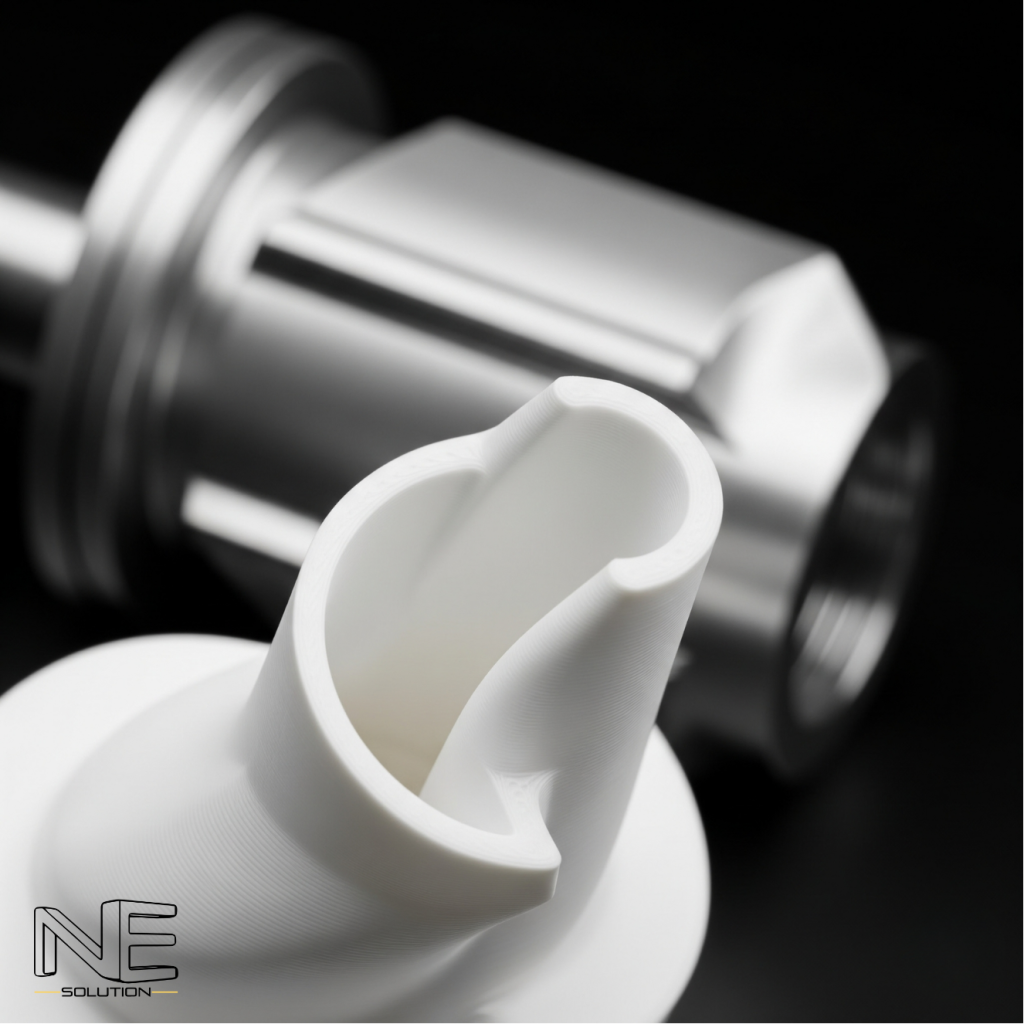

- Optimized Geometries for Cleanability (Clean-in-Place – CIP/Sterilize-in-Place – SIP): Additive manufacturing allows engineers to design components with smoother surfaces, rounded internal angles, and self-draining properties. These features drastically reduce areas where food residues can accumulate and bacteria can form biofilms, which are highly resistant to cleaning agents. Specialized 3d printing services can work with food companies to redesign critical components like nozzles, valves, mixers, and conveyor parts to be inherently more hygienic and easier to clean.

- Consolidation of Parts: Traditional manufacturing often requires multiple parts to be assembled, creating seams, crevices, and joints where bacteria can lodge. 3D printing services can produce complex components as a single, consolidated piece, eliminating these risky interfaces. This not only improves hygiene but can also enhance the structural integrity and lifespan of the equipment.

- Food-Grade Materials & Sterilization: The portfolio of materials available for 3d printing services now includes a growing range of food-grade polymers (e.g., certain grades of PLA, PETG, Nylon, and specialized resins) that comply with FDA and EU regulations for food contact. Furthermore, parts produced by these 3d printing services can often be designed to withstand common sterilization methods used in the food industry, including autoclaving, chemical sterilization (e.g., with peracetic acid or hydrogen peroxide), or UV treatment. It is crucial to partner with 3d printing services that understand material biocompatibility and post-processing requirements for food applications.

- Rapid Prototyping and Iteration for Hygienic Design: Before committing to expensive tooling for mass production, food companies can use 3d printing services for rapid prototyping of new equipment designs. This allows for multiple iterations and testing of cleanability and functionality in a short timeframe and at a lower cost, ensuring the final design is optimized for food safety.

- Custom Grippers and End-Effectors for Robotics: As automation increases in food processing, 3D printed custom grippers and end-effectors for robotic arms can be designed for gentle handling of delicate food items and easy cleaning, reducing both contamination risks and product damage. These can be quickly redesigned and reprinted by 3d printing services as product lines change.

3. Intelligent and Safer Food Packaging Solutions through Additive Manufacturing

Food packaging is the first line of defense against external contaminants and plays a crucial role in extending shelf life. 3D printing services are unlocking new possibilities in creating smarter, safer, and more sustainable packaging.

- Rapid Prototyping of Novel Packaging Designs: Testing new packaging concepts can be slow and costly with traditional mold-making. 3D printing services enable designers to quickly produce physical prototypes of bottles, containers, and closures, allowing for functional testing (e.g., seal integrity, ergonomics) and consumer feedback much earlier in the design cycle.

- Active and Intelligent Packaging: This is a frontier where 3d printing services truly shine.

- Active Packaging: Incorporating materials directly into the 3D printed packaging structure that can actively improve food preservation, such as oxygen scavengers, moisture absorbers, or antimicrobial releasing agents.

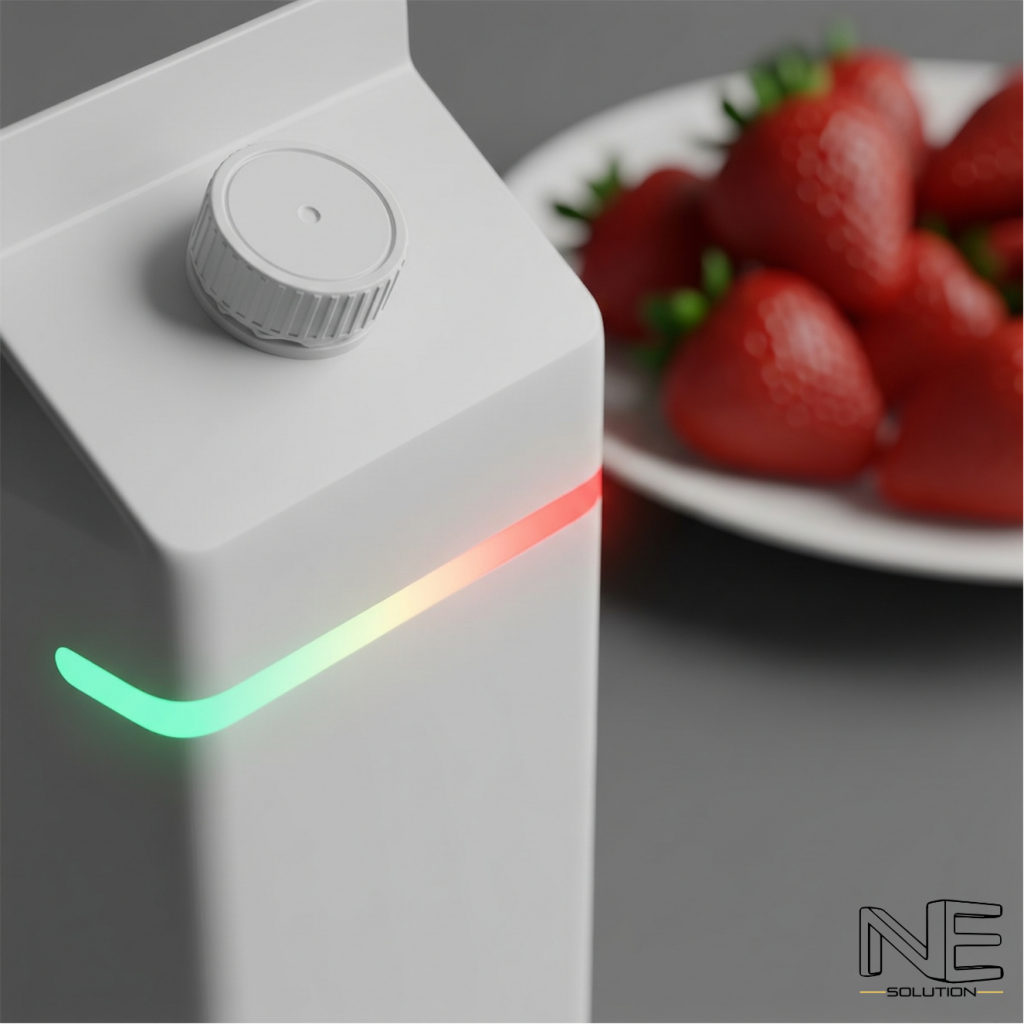

- Intelligent Packaging: Embedding 3D printed sensors or indicators within packaging that can monitor the condition of the food (e.g., temperature, freshness, pH) or the integrity of the package itself. Imagine a milk carton with a 3D printed strip that changes color if the cold chain is broken or if spoilage gases are detected.

- Customized Packaging for Enhanced Protection and Reduced Waste: 3D printing services allow for the creation of packaging perfectly tailored to the shape and size of the product. This can reduce the need for void-fill materials, minimize movement and damage during transit (which can compromise package integrity), and ultimately reduce food waste. On-demand printing of custom packaging also reduces the waste associated with obsolete packaging stock.

- Sustainable Materials and Designs: The push for sustainability is strong in the packaging industry. 3D printing services are increasingly working with biodegradable and recyclable polymers. Furthermore, the design freedom allows for lightweighting packaging without compromising strength, reducing material usage and transportation emissions.

- On-Demand and Decentralized Packaging Production: For specialized or low-volume products, 3d printing services can enable on-demand production of packaging components, reducing storage costs and lead times. In the future, this could even lead to decentralized packaging production closer to the point of packing or consumption.

4. Bespoke Tools for Enhanced Sanitation, Handling, and Maintenance

Effective cleaning protocols and safe handling practices are non-negotiable in any food processing environment, particularly in dairy facilities where microbial control is paramount. 3D printing services offer the capability to create custom tools that improve these critical operations.

- Ergonomic and Effective Cleaning Tools: Standard cleaning tools may not always be suitable for the complex geometries of modern food processing equipment. 3D printing services can design and produce bespoke brushes, scrapers, squeegees, and nozzles that are perfectly shaped to reach and effectively clean specific machine parts, ensuring no area is missed. These tools can be made from food-grade, durable, and color-coded materials to prevent cross-contamination.

- Custom Jigs, Fixtures, and Organizational Aids: Maintaining an organized and efficient workflow is crucial for safety. 3D printing services can create custom jigs to guide cutting or assembly operations, fixtures to hold components during cleaning or maintenance, and specialized trays or holders to organize tools and small parts, reducing the risk of misplacement or contamination.

- Rapid Replacement of Small Parts and Maintenance Tools: When a small, non-critical but essential part of a machine breaks (e.g., a knob, a guide, a specialized wrench for a unique fitting), waiting for an OEM replacement can lead to costly downtime. 3D printing services can often reverse-engineer and print a replacement part quickly, sometimes within hours, minimizing disruption and preventing temporary, potentially unsafe workarounds.

- Training Aids: Complex cleaning and assembly procedures can be better taught using 3D printed scale models of equipment or specific challenging parts, allowing staff to practice and understand the processes in a safe environment.

5. Bolstering Quality Control and Traceability with 3D Printed Precision

While not always a direct preventative for microbial growth, robust quality control (QC) and traceability systems are essential components of a comprehensive food safety strategy. 3D printing services contribute by providing tools that enhance precision and data capture.

- Custom Gauges and Inspection Fixtures: Ensuring dimensional accuracy of food products (e.g., portion sizes) or packaging components is vital. 3D printing services can create highly accurate custom gauges and fixtures that allow for quick and reliable go/no-go checks on the production line, improving consistency and quality.

- Integration with Automation: 3D printed components can be designed to interface seamlessly with automated inspection systems, such as machine vision cameras or robotic sensors, ensuring precise positioning of products for accurate QC checks.

- Embedding Traceability Features: While still an emerging area, research is exploring how 3d printing services can embed traceability elements like QR codes or even RFID micro-tags directly into packaging components or durable equipment parts during the printing process itself, offering a more robust and tamper-evident tracking solution.

Challenges and the Path Forward: Partnering with Expert 3D Printing Services

While the potential of 3d printing services in the food safety domain is immense, it’s important to acknowledge existing considerations. Scalability for direct mass production of food items themselves via 3D printing is still largely in developmental stages (though not the focus of this safety-oriented discussion). Regulatory approvals for new 3D printed food contact materials and applications require rigorous testing and validation. Furthermore, designing and implementing these advanced solutions requires specialized knowledge in material science, additive manufacturing processes, and food safety regulations.

This is precisely where partnering with experienced 3d printing services like nesolution.com.au becomes critical. Professional 3d printing services offer:

- Material Expertise: Guidance on selecting appropriate food-grade materials and ensuring compliance.

- Design for Additive Manufacturing (DfAM): Optimizing designs for hygiene, functionality, and printability.

- Process Validation: Ensuring consistency and quality in printed parts.

- Access to Advanced Equipment: Utilizing industrial-grade printers that offer higher precision, a wider range of materials, and better mechanical properties for end-use parts.

The Future is Additive: A Safer Food Ecosystem with 3D Printing Services

The a2 Milk recall, like others before it, serves as a potent catalyst for innovation. The food industry’s commitment to safety is unwavering, and the adoption of technologies like additive manufacturing will be pivotal in building an even more resilient and trustworthy food ecosystem. From the development of instant pathogen sensors to the printing of self-cleaning machine parts and intelligent packaging that communicates its status, 3d printing services are providing a powerful toolkit to anticipate, detect, and prevent food safety hazards.

As 3d printing services continue to evolve, with advancements in multi-material printing, AI-driven design optimization for safety, and more sustainable food-grade materials, their role in safeguarding our food supply will only expand. For food producers in Western Australia and beyond, exploring the potential of professional 3d printing services is not just about embracing novelty; it’s a strategic investment in risk mitigation, operational excellence, and consumer confidence.

Consumers impacted by the specific a2 Light Milk 2L recall mentioned (Use By 06/06 #41, WA only) should follow the advice of Food Standards Australia New Zealand (FSANZ) and the retailer: do not consume the product and return it to the point of purchase for a full refund. If there are health concerns after potential consumption, medical advice should be sought immediately. For the broader food industry, however, the true lesson lies in proactively seeking solutions that ensure such recalls become increasingly rare. 3D printing services are a key part of that proactive future.